When it comes to choosing the ideal belt pulley for a conveyor belt system, there are a few factors you’ll need to take into account. What type of material will the belt be made out of? What is the size and shape of the pulley? And what type of shaft will it fit onto? There are quite a few factors that you need to consider before making your choice. In this article, we will discuss the different types of belt pulleys and help you choose the perfect one to match your needs.

What is a belt conveyor pulley?

A belt conveyor pulley is a type of mechanical pulley that is used to power a belt conveyor system. It is typically made from metal or plastic and is mounted on a shaft that rotates to move the belt. There are different types of belt conveyor pulleys, including grooved pulleys, crowned pulleys, and V-belts.

Grooved pulleys have a series of ridges or grooves on the surface that grip the belt and keep it in place. Crowned pulleys have a curved surface that presses down on the belt and helps keep it in position. V-belts are shaped like a V, with two flat surfaces that grip the sides of the belt.

Ineffective conveyor belt pulley choices cause problems in construction industry projects, which is why knowing which one to get is so critical. Choosing one can be challenging, which is why we’ll overview some of the many different kinds of conveyor pulleys to help you get started.

Grooved conveyor pulleys

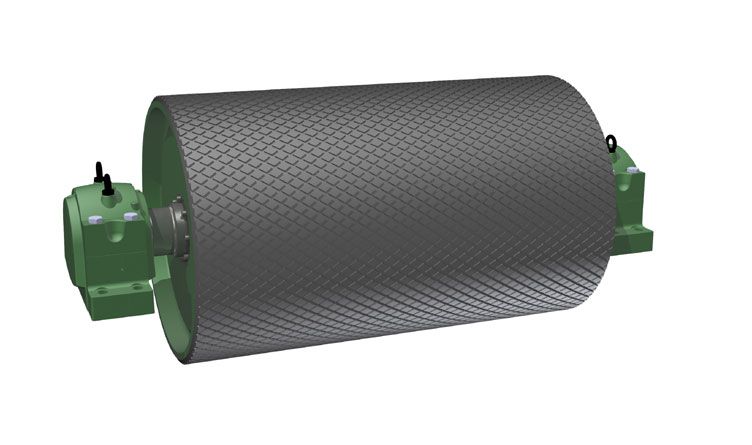

Grooved conveyor pulleys are the most common type of belt pulley. They have a series of ridges or grooves on the surface that grip the belt and keep it in place. This type of pulley is easy to use and is perfect for applications where a lot of power is needed.

However, the downside of grooved pulleys is that they can cause the belt to slip if not used correctly.

Crowned conveyor pulleys

Crowned conveyor pulleys are another type of belt pulley. They are designed with a curved surface that presses down on the belt and helps keep it in position. This type of pulley is often used in high-speed applications where the belt needs to be kept in place

They have a curved surface that presses down on the belt and helps keep it in position. Crowned pulleys are ideal for applications where speed is important, such as in a manufacturing setting.

Welded steel belt pulleys

Welded steel belt pulleys are a type of belt pulley that is made from welded steel. They are durable and can withstand heavy loads, making them perfect for applications where a lot of power and durability are needed.

Welded steel belt pulleys are also resistant to wear and tear, which makes them a good choice for high-speed applications.

Spiral wing belt pulleys

Spiral wing belt conveyor pulleys are a type of belt pulley that is designed with spiral wings on the surface. This type of pulley is often used in high-speed applications where the belt needs to be kept in place.

The spiral wings on the surface of the pulley help to keep the belt in place, while also providing extra gripping power. This makes them a good choice for applications where speed is important.

V-belt pulleys

V-belt pulleys are another type of belt pulley that can be used in a belt conveyor system. They are shaped like a V, with two flat surfaces that grip the sides of the belt. They are more commonly used for power transmission than other types of durable belt pulleys.

This type of pulley is often used in high-speed applications where the belt needs to be kept in place. V-belt pulleys are also durable and can withstand heavy loads.

Which belt pulley should you choose?

As you can see, each type of belt pulley has its specific benefits and uses in a conveyor system. Which one you choose will depend on your specific needs.

To help you choose the right type of belt pulley, ask yourself these questions:

- What is the application?

- What is the power needed?

- How much durability is required?

- Is speed a factor?

Different conveyor systems will require different types of belt pulleys, so it’s not an easy choice. Once you have answered these questions, you will be able to narrow down your options and choose the perfect belt pulley for your needs.

Conclusion

We hope this guide was helpful in understanding the different types of belt pulleys and their benefits. When choosing a belt pulley for your needs, be sure to consider the application, the power needed, the durability required, and whether or not speed is a factor. At the same time, consider the drawbacks of each type of belt pulley before you choose one for your conveyor system. With this information, you will be able to narrow down your options and choose the perfect belt pulley for your needs.

Reblog It collaborates closely with clients to develop tailored guest posting strategies that align with their unique goals and target audiences. Their commitment to delivering high-quality, niche-specific content ensures that each guest post not only meets but exceeds the expectations of both clients and the hosting platforms. Connect with us on social media for the latest updates on guest posting trends, outreach strategies, and digital marketing tips. For any types of guest posting services, contact us on reblogit.webmail[at]gmail.com.